Metal Products we offer:

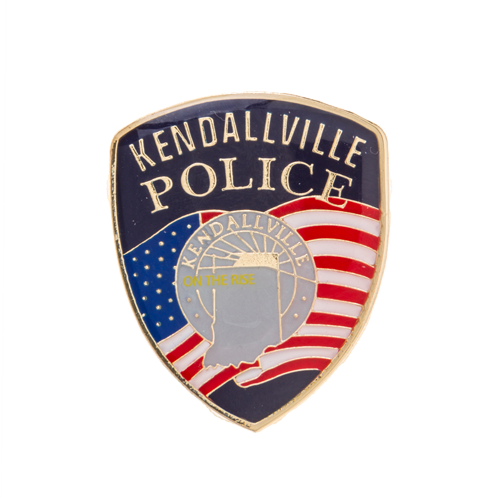

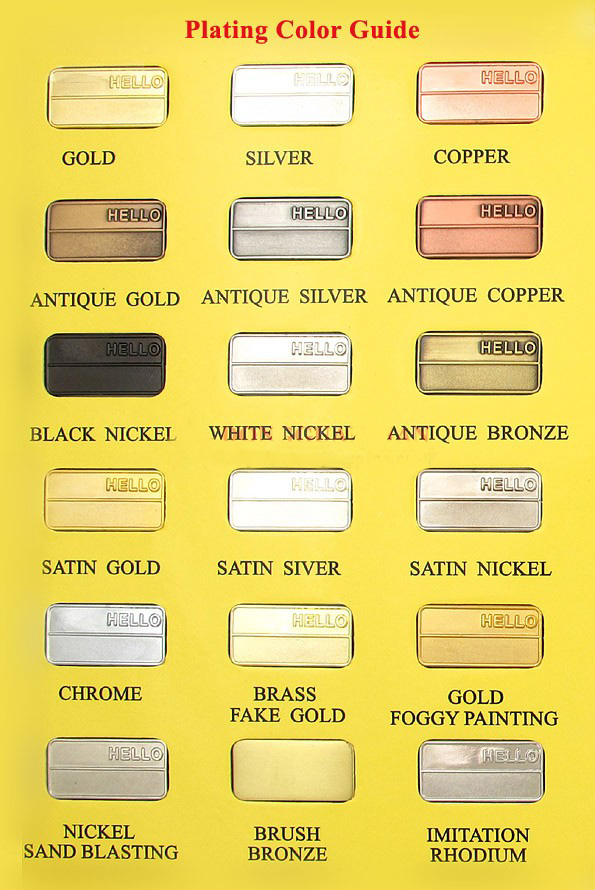

Lapel Pins

A lapel pin is a small pin worn on clothing to show affiliation with an organization or cause. Pins have one or more post with some sort of attachment, usually a butterfly clutch or rubber backing.

Keychains

A metal key chain can be a smaller version of your patch or logo. These make a great gift idea, too!

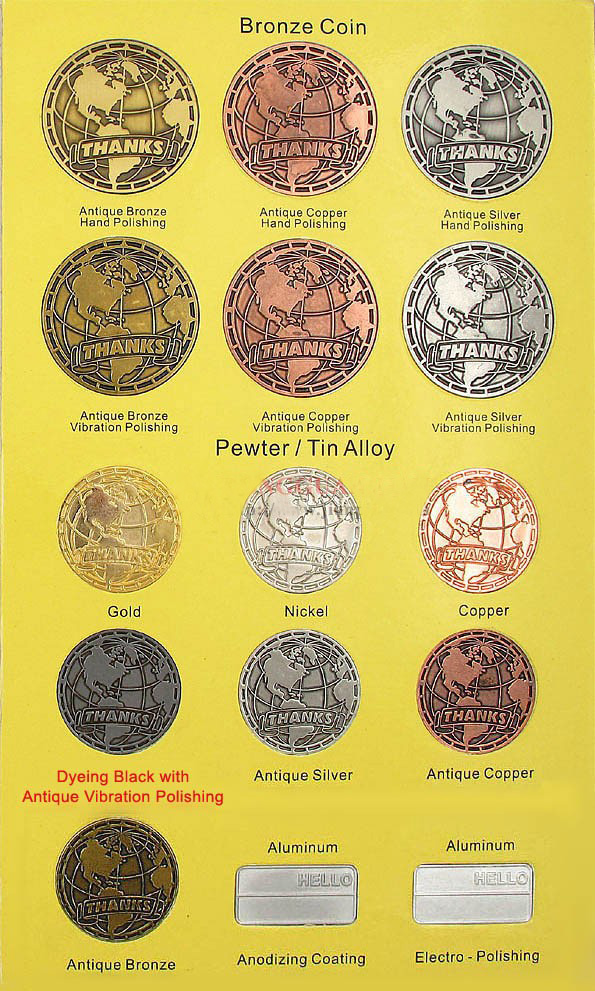

Coins

A challenge coin is a small coin or medallion, bearing an organization’s insignia or emblem and carried by the organization’s members. They began with the Military but are now used across Public Safety and other sectors. Traditionally, they are given to prove membership when challenged and to enhance morale. In addition, they are also collected by service members.